[1]ZHENG Jing,XIONG Weili.Multiblock k-nearest neighbor fault monitoring and diagnosis based on mutual information[J].CAAI Transactions on Intelligent Systems,2021,16(4):717-728.[doi:10.11992/tis.202007035]

Copy

Multiblock k-nearest neighbor fault monitoring and diagnosis based on mutual information

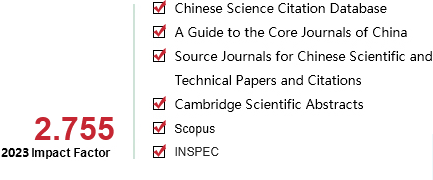

CAAI Transactions on Intelligent Systems[ISSN 1673-4785/CN 23-1538/TP] Volume:

16

Number of periods:

2021 4

Page number:

717-728

Column:

学术论文—智能系统

Public date:

2021-07-05

- Title:

- Multiblock k-nearest neighbor fault monitoring and diagnosis based on mutual information

- Keywords:

- mutual information; multi-block modeling; k-nearest neighbor; process monitoring; fault detection; Bayesian inference; fault diagnosis; Mahalanobis distance

- CLC:

- TP277

- DOI:

- 10.11992/tis.202007035

- Abstract:

- The traditional k-nearest neighbor (kNN) fault monitoring does not take into account the process of local information and only builds a global model. Thus, a multi-block kNN fault monitoring algorithm based on mutual information is proposed. First, with the nonlinear and non-Gaussian characteristics of the modeled data taken into consideration, subblocks are constructed based on mutual information between variables. Then, the kNN algorithm is used to model and monitor each subblock, in which the kNN model reflects more local characteristics of the process. Lastly, the monitoring results of all subblocks are fused by the Bayesian inference method, and a fault diagnosis method based on Mahalanobis distance is used to identify the source of faults. Through the application simulation in the Tennessee Eastman process and the blast furnace ironmaking process, the monitoring results show the feasibility and effectiveness of the proposed method.

- References:

-

[1] CHIANG L H, RUSSELL E L, BRAATZ R D. Fault detection and diagnosis in industrial systems[J]. Measurement science and technology, 2001, 12(10): 1745.

[2] GE Zhiqiang, SONG Zhihuan, GAO Furong. Review of recent research on data-based process monitoring[J]. Industrial & engineering chemistry research, 2013, 52(10): 3534-3562.

[3] QIN S J. Statistical process monitoring: basics and beyond[J]. Journal of chemometrics, 2003, 17(8/9): 480-502.

[4] JIANG Qingchao, YAN Xuefeng, ZHAO Weixiang. Fault detection and diagnosis in chemical processes using sensitive principal component analysis[J]. Industrial & engineering chemistry research, 2013, 52(4): 1635-1644.

[5] KRESTA J V, MACGREGOR J F, MARLIN T E. Multivariate statistical monitoring of process operating performance[J]. The Canadian journal of chemical engineering, 1991, 69(1): 35-47.

[6] NOMIKOS P, MACGREGOR J F. Multivariate SPC charts for monitoring batch processes[J]. Technometrics, 1995, 37(1): 41-59.

[7] HE Q P, WANG Jin. Principal component based k-nearest-neighbor rule for semiconductor process fault detection[C]//Proceedings of 2018 American Control Conference. Seattle, USA, 2008: 1606-1611.

[8] HE Q P, WANG Jin. Fault detection using the k-Nearest neighbor rule for semiconductor manufacturing processes[J]. IEEE transactions on semiconductor manufacturing, 2007, 20(4): 345-354.

[9] 陈海彬, 郭金玉, 谢彦红. 基于改进K-means聚类的kNN故障检测研究[J]. 沈阳化工大学学报, 2013, 27(1): 69-73

CHEN Haibin, GUO Jinyu, XIE Yanhong. kNN fault detection based on improved K-means clustering[J]. Journal of Shenyang University of Chemical Technology, 2013, 27(1): 69-73

[10] 魏域琴, 宋丹丹, 翁正新. 基于DPCA-KNN的工业过程故障诊断方法研究[C]//第三十八届中国控制会议论文集(7). 广州, 2019: 14-19.

WEI Yuqin, SONG Dandan, WENG Zhengxin. Research on fault diagnosis method of industrial process based on DPCA-KNN[C]//Proceedings of the 38th China Control Conference. Guangzhou, 2019: 14-19.

[11] 郭小萍, 徐月, 李元. 基于特征空间自适应k近邻工业过程故障检测[J]. 高校化学工程学报, 2019, 33(2): 453-461

GUO Xiaoping, XU Yue, LI Yuan. A feature space adaptive k-nearest neighbor method for industrial fault detection[J]. Journal of chemical engineering of Chinese universities, 2019, 33(2): 453-461

[12] 冯立伟, 张成, 李元, 等. 基于标准距离k近邻的多模态过程故障检测策略[J]. 控制理论与应用, 2019, 36(4): 553-560

FENG Liwei, ZHANG Cheng, LI Yuan, et al. Fault detection strategy of standard-distance-based k nearest neighbor rule in multimode processes[J]. Control theory & applications, 2019, 36(4): 553-560

[13] MACGREGOR J F, JAECKLE C, KIPARISSIDES C, et al. Process monitoring and diagnosis by multiblock PLS methods[J]. AIChE journal, 1994, 40(5): 826-838.

[14] 王振雷, 江伟, 王昕. 基于多块MICA-PCA的全流程过程监控方法[J]. 控制与决策, 2018, 33(2): 269-274

WANG Zhenlei, JIANG Wei, WANG Xin. Plant-wide process monitoring based on multiblock MICA-PCA[J]. Control and decision, 2018, 33(2): 269-274

[15] 石怀涛, 王雨桐, 李颂华, 等. 基于多块相对变换独立主元分析的故障诊断方法[J]. 控制与决策, 2018, 33(11): 2009-2014

SHI Huaitao, WANG Yutong, LI Songhua, et al. Fault diagnosis approach based on relative transformation ICA of multiblock[J]. Control and decision, 2018, 33(11): 2009-2014

[16] GE Zhiqiang, SONG Zhihuan. Distributed PCA model for plant-wide process monitoring[J]. Industrial & engineering chemistry research, 2013, 52(5): 1947-1957.

[17] JIANG Qingchao, YAN Xuefeng. Plant-wide process monitoring based on mutual information-multiblock principal component analysis[J]. ISA transactions, 2014, 53(5): 1516-1527.

[18] HUANG Junping, YAN Xuefeng. Quality relevant and independent two block monitoring based on mutual information and KPCA[J]. IEEE transactions on industrial electronics, 2017, 64(8): 6518-6527.

[19] JIANG Qingchao, YAN Xuefeng. Nonlinear plant-wide process monitoring using MI-spectral clustering and Bayesian inference-based multiblock KPCA[J]. Journal of process control, 2015, 32: 38-50.

[20] 童楚东, 史旭华. 基于互信息的PCA方法及其在过程监测中的应用[J]. 化工学报, 2015, 66(10): 4101-4106

TONG Chudong, SHI Xuhua. Mutual information based PCA algorithm with application in process monitoring[J]. CIESC journal, 2015, 66(10): 4101-4106

[21] 范雪莉, 冯海泓, 原猛. 基于互信息的主成分分析用于声场景分类[J]. 声学技术, 2013, 32(3): 222-227

FAN Xueli, FENG Haihong, YUAN Meng. Mutual information based principal component analysis for acoustic environment classification[J]. Technical acoustics, 2013, 32(3): 222-227

[22] 周红标, 乔俊飞. 基于高维k-近邻互信息的特征选择方法[J]. 智能系统学报, 2017, 12(5): 595-600

ZHOU Hongbiao, QIAO Junfei. Feature selection method based on high dimensional k-nearest neighbors mutual information[J]. CAAI transactions on intelligent systems, 2017, 12(5): 595-600

[23] GE Zhiqiang, SONG Zhihuan. Multimode process monitoring based on Bayesian method[J]. Journal of chemometrics, 2009, 23(12): 636-650.

[24] YIN Shen, DING S X, HAGHANI A, et al. A comparison study of basic data-driven fault diagnosis and process monitoring methods on the benchmark Tennessee Eastman process[J]. Journal of process control, 2012, 22(9): 1567-1581.

[25] CHIANG L H, RUSSELL E L, BRAATZ R D. Tennessee Eastman process[M]//CHIANG L H, RUSSELL E L, BRAATZ R D. Fault Detection and Diagnosis in Industrial Systems. London: Springer, 2001: 103-112.

- Similar References:

Memo

-

Last Update:

1900-01-01