[1]WANG Yufang,ZHANG Yi,YAO Binbin,et al.Flexible job shop scheduling considering transportation and machine pre-maintenance[J].CAAI Transactions on Intelligent Systems,2025,20(3):707-718.[doi:10.11992/tis.202405020]

Copy

Flexible job shop scheduling considering transportation and machine pre-maintenance

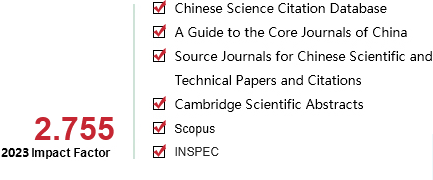

CAAI Transactions on Intelligent Systems[ISSN 1673-4785/CN 23-1538/TP] Volume:

20

Number of periods:

2025 3

Page number:

707-718

Column:

学术论文—智能系统

Public date:

2023-05-05

- Title:

- Flexible job shop scheduling considering transportation and machine pre-maintenance

- Keywords:

- transportation constraint; pre-maintenance; aerospace manufacturing; NSGA-II; population quality; group evolution; heuristic initialization; local search

- CLC:

- TP18;TH165

- DOI:

- 10.11992/tis.202405020

- Abstract:

- The rapid development of the aviation manufacturing industry has increased the demand for high-efficiency and low-energy modes of consumption and production. Here, a modeling and analysis approach was employed to address the green scheduling issues of an aerospace flexible job shop regarding transportation and pre-maintenance. Additionally, a model was established to minimize the completion time, bottleneck machine workload, and total energy consumption. Further, non-dominated sorting genetic algorithm II based on population quality was proposed to resolve the issues. Furthermore, heuristic initialization was employed to generate high-quality initial populations, and individuals were grouped to evolve. Thereafter, local search operations were conducted to comprehensively explore the optimal individuals. For the populations classified as moderate, crossover and mutation combined with machine load operations were applied to alter portions of their genetic makeup and achieve optimal solutions. Employing a learning mechanism, the inferior populations acquired superior genes from elite individuals to enhance their overall quality. Subsequently, the effectiveness of the proposed algorithm was verified by comparing it with those of other algorithms on test examples. Finally, the algorithm was applied to a real aerospace composite material manufacturing system to schedule actual production activities, thereby verifying its feasibility.

- References:

-

[1] WU Mingliang, YANG Dongsheng, ZHOU Bowen, et al. Adaptive population NSGA-III with dual control strategy for flexible job shop scheduling problem with the consideration of energy consumption and weight[J]. Machines, 2021, 9(12): 344.

[2] LI Yibin, HUANG Weixing, WU R, et al. An improved artificial bee colony algorithm for solving multi-objective low-carbon flexible job shop scheduling problem[J]. Applied soft computing, 2020, 95: 106544.

[3] 吴秀丽, 张志强, 赵宁, 等. 超启发式文化基因算法优化生产与预维修集成调度问题[J]. 计算机集成制造系统, 2019, 25(8): 1885-1896.

WU Xiuli, ZHANG Zhiqiang, ZHAO Ning, et al. Production scheduling and preventive maintenance plan optimization with hyper-heuristics memetic algorithm[J]. Computer integrated manufacturing systems, 2019, 25(8): 1885-1896.

[4] 李聪波, 王睿, 寇阳, 等. 考虑设备预维护的柔性作业车间调度节能优化方法[J]. 机械工程学报, 2021, 57(10): 220-230.

LI Congbo, WANG Rui, KOU Yang, et al. Energy saving optimization method of flexible job shop scheduling considering preventive maintenance[J]. Journal of mechanical engineering, 2021, 57(10): 220-230.

[5] WOCKER M M, OSTERMEIER F F, WANNINGER T, et al. Flexible job shop scheduling with preventive maintenance consideration[J]. Journal of intelligent manufacturing, 2023, 35(4): 1-23.

[6] NIKOLAOS R, LI An, ZHANG An, et al. Novel approach to energy-efficient flexible job-shop scheduling problems[J]. Energy, 2022, 238: 121773.

[7] MENG Leilei, REN Yaping, ZHANG Biao, et al. MILP modeling and optimization of energy-efficient distributed flexible job shop scheduling problem[J]. IEEE access, 2020, 8: 191191-191203.

[8] 王凌, 王晶晶. 考虑运输时间的分布式绿色柔性作业车间调度协同群智能优化[J]. 中国科学: 技术科学, 2023, 53(2): 243-257.

WANG Ling, WANG Jingjing. A cooperative memetic algorithm for the distributed green flexible job shop with transportation time[J]. SCIENTIA SINICA technologica, 2023, 53(2): 243-257.

[9] JIANG Tianhua, ZHU Huiqi, LIU Lu, et al. Energy-conscious flexible job shop scheduling problem considering transportation time and deterioration effect simultaneously[J]. Sustainable computing: informatics and systems, 2022, 35: 100680.

[10] 柳冬, 宋豫川, 杨云帆, 等. 机器故障的柔性加工与装配作业车间分批联合调度算法[J]. 智能系统学报, 2022, 17(3): 556-567.

LIU Dong, SONG Yuchuan, YANG Yunfan, et al. Batch scheduling algorithm for flexible machining and assembly job shop when the machine breaks down[J]. CAAI transactions on intelligent systems, 2022, 17(3): 556-567.

[11] SUN Wei, PAN Ying, LU Xiaohong, et al. Research on flexible job-shop scheduling problem based on a modified genetic algorithm[J]. Journal of mechanical science and technology, 2010, 24(10): 2119-2125.

[12] WU J, WU G D, WANG J J. Flexible job-shop scheduling problem based on hybrid aco algorithm[J]. International journal of simulation modelling, 2017, 16(3): 497-505.

[13] NOUIRI M, BEKRAR A, JEMAI A. Two stage particle swarm optimization to solve the flexible job shop predictive scheduling problem considering possible machine breakdowns[J]. Computers & industrial engineering, 2017, 112: 595-606.

[14] ZHOU K, TAN C H, ZHAO Y, et al. Research on solving flexible job shop scheduling problem based on improved GWO algorithm SS-GWO[J]. Neural processing letters, 2024, 56(1): 288-298.

[15] ADIRI I, FROSTIG E, KAN A H G R. Scheduling on a single machine with a single breakdown to minimize stochastically the number of tardy jobs[J]. Naval research logistics (NRL), 1991, 38(2): 261-271.

[16] 常建涛, 史尊博, 符博峰, 等. 一种多品种变批量柔性作业车间调度方法[J]. 电子机械工程, 2022, 38(5): 60-64.

CHANG Jiantao, SHI Zunbo, FU Bofeng, et al. A scheduling method for multi-variety variable batch flexible job shop[J]. Electro-mechanical engineering, 2022, 38(5): 60-64.

[17] ASADZADEH L. A local search genetic algorithm for the job shop scheduling problem with intelligent agents[J]. Computers & industrial engineering, 2015, 85: 376-383.

[18] WANG L, WANG S Y, LIU M. A Pareto-based estimation of distribution algorithm for the multi-objective flexible job-shop scheduling problem[J]. International journal of production research, 2013, 51(12): 3574-3592.

[19] MOKHTARI H, HASANI A. An energy-efficient multi-objective optimization for flexible job-shop scheduling problem[J]. Computers & chemical engineering, 2017, 104: 339-352.

[20] 赵文超, 郭鹏, 王海波, 等. 改进樽海鞘群算法求解柔性作业车间调度问题[J]. 智能系统学报, 2022, 17(2): 376-386.

ZHAO Wenchao, GUO Peng, WANG Haibo, et al. Improved slap swarm algorithm for scheduling of flexible job shop[J]. CAAI transactions on intelligent systems, 2022, 17(2): 376-386.

[21] 张超勇, 饶运清, 刘向军, 等. 基于POX交叉的遗传算法求解Job-Shop调度问题[J]. 中国机械工程, 2004(23): 83-87.

ZHANG Chaoyong, RAO Yunqing, LIU Xiangjun, et al. An improved genetic algorithm or the Job-Shop scheduling problem[J]. China mechanical engineering, 2004(23): 83-87.

[22] BRANDIMARTE P. Routing and scheduling in a flexible job shop by tabu search[J]. Annals of operations research, 1993, 41(3): 157-183.

[23] BOSMAN P A N, THIERENS D. The balance between proximity and diversity in multiobjective evolutionary algorithms[J]. IEEE transactions on evolutionary computation, 2003, 7(2): 174-188.

[24] KHARE A, AGRAWAL S. Scheduling hybrid flowshop with sequence-dependent setup times and due windows to minimize total weighted earliness and tardiness[J]. Computers & industrial engineering, 2019, 135: 780-792.

[25] WHILE L, HINGSTON P, BARONE L, et al. A faster algorithm for calculating hypervolume[J]. IEEE transactions on evolutionary computation., 2006, 10(1): 29-38.

[26] WANG Y F, GE J R, MIAO S, et al. Application of hybrid artificial bee colony algorithm based on load balancing in aerospace composite material manufacturing[J]. Expert systems with application, 2023, 215: 119375.

[27] 张洪亮, 徐公杰, 鲍蔷, 等. 考虑运输时间和机器预维护的柔性作业车间绿色调度[J]. 计算机集成制造系统, 2024, 30(9): 3111-3124.

ZHANG Honliang, XU Gonjie, BAO Qiang, et al. Flexible job-shop green scheduling considering transportation time and machine preventive maintenance[J]. Computer integrated manufacturing systems, 2024, 30(9): 3111-3124.

[28] WANG H, SHENG B, LU Q, et al. A novel multi-objective optimization algorithm for the integrated scheduling of flexible job shops considering preventive maintenance activities and transportation processes[J]. Soft computing, 2021, 25(4): 1-27.

[29] LI M, LEI D. An imperialist competitive algorithm with feedback for energy-efficient flexible job shop scheduling with transportation and sequence-dependent setup times[J]. Engineering applications of artificial intelligence, 2021, 103: 104307.

[30] ZITZLER E. Multiobjective evolutionary algorithms: A comparative case study and the strength pareto approach[J]. IEEE transactions on evolutionary computation, 1999, 3(4): 257-271.

- Similar References:

Memo

-

Last Update:

1900-01-01