[1]TANG Jialu,YANG Zhongliang,ZHANG Song,et al.Detection of yarn hairiness combining microscopic vision and attention mechanism[J].CAAI Transactions on Intelligent Systems,2022,17(6):1209-1219.[doi:10.11992/tis.202112035]

Copy

Detection of yarn hairiness combining microscopic vision and attention mechanism

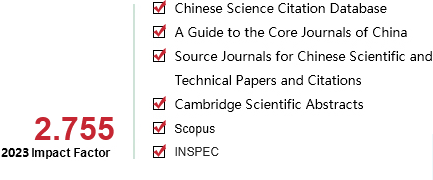

CAAI Transactions on Intelligent Systems[ISSN 1673-4785/CN 23-1538/TP] Volume:

17

Number of periods:

2022 6

Page number:

1209-1219

Column:

学术论文—智能系统

Public date:

2022-11-05

- Title:

- Detection of yarn hairiness combining microscopic vision and attention mechanism

- Keywords:

- object detection; micro vision; attention mechanism; yarn package; defect detection; illumination engineering; deep learning; feature fusion

- CLC:

- TP391;TP41

- DOI:

- 10.11992/tis.202112035

- Abstract:

- Broken ends of yarns are difficult to detect due to their small features, which are easily overlooked and confused. To detect defects accurately and efficiently in the appearance of polyester yarn packages, an image acquisition platform with a microscopic camera was designed, and a defect detection algorithm (CenterNet-CBAM) with an attention mechanism and feature fusion was proposed. Two types of confusing target images, yarn hairiness, and broken ends were collected to design an objective model of CenterNet-CBAM, which was compared with four other object detection algorithms, CenterNet, YOLOv4, Faster R-CNN, and SSD. The results show that the industrial microscope camera can acquire the feature of yarn hairiness. The precision of CenterNet-CBAM for yarn hairiness and broken ends is 94.00% and 93.57%, the recall rates are 86.75% and 92.16%, AP values are 92.93% and 92.91%, respectively, and the mAP values are 92.92%. Better results in defect detection compared to other algorithms demonstrate the validity of the experiment method.

- References:

-

[1] 孙建奎, 王勃. 165dtex/36f涤纶FDY绊丝产生原因分析及对策[J]. 合成纤维, 2021, 50(10): 4–7

SUN Jiankui, WANG Bo. Discussion on the causes and countermeasures of overthrown yarn with 165 dtex/36 f polyester FDY[J]. Synthetic fiber in China, 2021, 50(10): 4–7

[2] 赵博. 减少纯化纤纱毛羽的研究与探讨[J]. 化纤与纺织技术, 2007, 36(4): 11–15

ZHAO Bo. Discussion and research of reducing the pure chemical fibre yarn hairiness[J]. Chemical fiber & textile technology, 2007, 36(4): 11–15

[3] ARENTS J, GREITANS M. Smart industrial robot control trends, challenges and opportunities within manufacturing[J]. Applied sciences, 2022, 12(2): 937.

[4] TOUNSADI H, METARFI Y, TALEB M, et al. Impact of chemical substances used in textile industry on the employee’s health: Epidemiological study[J]. Ecotoxicology and environmental safety, 2020, 197: 110594.

[5] RASMUSSE J. Human error mechanisms in complex work environments[J]. Reliability engineering & system safety, 1988, 22(1/2/3/4): 155–167.

[6] ACEMOGLU D, RESTREPO P. The race between man and machine: implications of technology for growth, factor shares, and employment[J]. American economic review, 2018, 108(6): 1488–1542.

[7] FABIJA?SKA A, JACKOWSKA-STRUMI??O L. Image processing and analysis algorithms for yarn hairiness determination[J]. Machine vision and applications, 2012, 23(3): 527–540.

[8] BISSI L, BARUFFA G, PLACIDI P, et al. Patch based yarn defect detection using Gabor filters[C]//2012 IEEE International Instrumentation and Measurement Technology Conference Proceedings. Graz: IEEE, 2012: 240-244.

[9] 李东洁, 郭帅, 杨柳. 基于改进图像阈值分割算法的纱线疵点检测[J]. 纺织学报, 2021, 42(3): 82–88

LI Dongjie, GUO Shuai, YANG Liu. Yarn defect detection based on improved image threshold segmentation algorithm[J]. Journal of textile research, 2021, 42(3): 82–88

[10] 李彦, 朱凌云. 基于图像处理的纽扣轮廓瑕疵检测[J]. 东华大学学报(自然科学版), 2021, 47(4): 69–74,134

LI Yan, ZHU Lingyun. Detection of button contour defects based on image processing[J]. Journal of Donghua University (natural science edition), 2021, 47(4): 69–74,134

[11] REN Shaoqing, HE Kaiming, GIRSHICK R, et al. Faster R-CNN: towards real-time object detection with region proposal networks[J]. IEEE transactions on pattern analysis and machine intelligence, 2017, 39(6): 1137–1149.

[12] 车翔玖, 刘华罗, 邵庆彬. 基于Fast RCNN改进的布匹瑕疵识别算法[J]. 吉林大学学报(工学版), 2019, 49(6): 2038–2044

CHE Xiangjiu, LIU Hualuo, SHAO Qingbin. Fabric defect recognition algorithm based on improved Fast RCNN[J]. Journal of Jilin University (engineering and technology edition), 2019, 49(6): 2038–2044

[13] REDMON J, DIVVALA S, GIRSHICK R, et al. You only look once: unified, real-time object detection[C]//2016 IEEE Conference on Computer Vision and Pattern Recognition. Las Vegas: IEEE, 2016: 779-788.

[14] 唐有赟, 盛晓伟, 徐洋, 等. 基于轻量级模型的经编布瑕疵在线检测算法[J]. 东华大学学报(自然科学版), 2020, 46(6): 922–928

TANG Youyun, SHENG Xiaowei, XU Yang, et al. Online defect detection algorithm of warp knitting fabric based on lightweight model[J]. Journal of Donghua University (natural science edition), 2020, 46(6): 922–928

[15] 王泽霞, 陈革, 陈振中. 基于改进卷积神经网络的化纤丝饼表面缺陷识别[J]. 纺织学报, 2020, 41(4): 39–44

WANG Zexia, CHEN Ge, CHEN Zhenzhong. Surface defect recognition of chemical fiber yarn packages based on improved convolutional neural network[J]. Journal of textile research, 2020, 41(4): 39–44

[16] 张君扬, 景军锋. 应用激光三角测量法的化纤丝饼毛羽检测[J]. 西安工程大学学报, 2020, 34(3): 19–25

ZHANG Junyang, JING Junfeng. Hairiness detection of chemical fiber DTY packages using laser triangulation[J]. Journal of Xi’an Polytechnic University, 2020, 34(3): 19–25

[17] LIU Wei, ANGUELOV D, ERHAN D, et al. SSD: single shot MultiBox detector[M]//Computer Vision-ECCV 2016. Cham: Springer International Publishing, 2016: 21-37.

[18] 徐德. 显微视觉测量与控制[M]. 北京: 国防工业出版社, 2014.

[19] GESSERT N, BENGS M, WITTIG L, et al. Deep transfer learning methods for colon cancer classification in confocal laser microscopy images[J]. International journal of computer assisted radiology and surgery, 2019, 14(11): 1837–1845.

[20] 路凯, 钟跃崎, 朱俊平, 等. 基于视觉词袋模型的羊绒与羊毛快速鉴别方法[J]. 纺织学报, 2017, 38(7): 130–134,141

LU Kai, ZHONG Yueqi, ZHU Junping, et al. Rapid identification method of cashmere and wool based on bag-of-visual-word[J]. Journal of textile research, 2017, 38(7): 130–134,141

[21] KISANTAL M, WOJNA Z, MURAWSKI J, et al. Augmentation for small object detection[EB/OL].(2019-04-16)[2021-12-15].https://arxiv.org/abs/1902.07296v1.

[22] TONG Kang, WU Yiquan, ZHOU Fei. Recent advances in small object detection based on deep learning: a review[J]. Image and vision computing, 2020, 97: 103910.

[23] MA Xinshu, LI Xiaohuan, TANG Xin, et al. Deconvolution Feature Fusion for traffic signs detection in 5G driven unmanned vehicle[J]. Physical communication, 2021, 47: 101375.

[24] HAN Chaojun, SHEN Fumin, LIU Li, et al. Visual spatial attention network for relationship detection[C]//MM’18: Proceedings of the 26th ACM International Conference on Multimedia. New York: ACM, 2018: 510-518.

[25] 赵文清, 周震东, 翟永杰. 基于反卷积和特征融合的SSD小目标检测算法[J]. 智能系统学报, 2020, 15(2): 310–316

ZHAO Wenqing, ZHOU Zhendong, ZHAI Yongjie. SSD small target detection algorithm based on deconvolution and feature fusion[J]. CAAI transactions on intelligent systems, 2020, 15(2): 310–316

[26] ZHOU XINGYI, WANG DEQUAN, KR?HENBüHL P. Objects as points[EB/OL].(2019-02-19)[2021-12-15]. https://arxiv.org/abs/1904.07850.

[27] NAZIR T, NAWAZ M, RASHID J, et al. Detection of diabetic eye disease from retinal images using a deep learning based CenterNet model[J]. Sensors (Basel, Switzerland), 2021, 21(16): 5283.

[28] 张宸嘉, 朱磊, 俞璐. 卷积神经网络中的注意力机制综述[J]. 计算机工程与应用, 2021, 57(20): 64–72

ZHANG Chenjia, ZHU Lei, YU Lu. Review of attention mechanism in convolutional neural networks[J]. Computer engineering and applications, 2021, 57(20): 64–72

[29] HU Jie, SHEN Li, SUN Gang. Squeeze-and-excitation networks[C]//2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition. Salt Lake City: IEEE, 2018: 7132-7141.

[30] 江培营, 陶青川, 艾梦琴. 基于注意力机制和深度学习的钢板表面缺陷图像分类[J]. 计算机应用与软件, 2021, 38(9): 214–219

JIANG Peiying, TAO Qingchuan, AI Mengqin. Steel surface defect image classification based on attention mechanism and deep learning[J]. Computer applications and software, 2021, 38(9): 214–219

- Similar References:

Memo

-

Last Update:

1900-01-01