[1]CHEN Lichao,YAN Yaodong,ZHANG Rui,et al.Welding defect classification of stainless steel based on AlexNet neural network combined with transfer learning[J].CAAI Transactions on Intelligent Systems,2021,16(3):537-543.[doi:10.11992/tis.202005013]

Copy

Welding defect classification of stainless steel based on AlexNet neural network combined with transfer learning

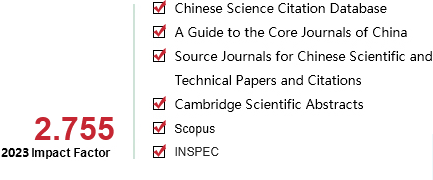

CAAI Transactions on Intelligent Systems[ISSN 1673-4785/CN 23-1538/TP] Volume:

16

Number of periods:

2021 3

Page number:

537-543

Column:

学术论文—人工智能基础

Public date:

2021-05-05

- Title:

- Welding defect classification of stainless steel based on AlexNet neural network combined with transfer learning

- Keywords:

- classification of weld defects in stainless steel; convolutional neural network; image preprocessing; AlexNet model; the migration study; data enhancement; weld data set; deep learning

- CLC:

- TP391.4

- DOI:

- 10.11992/tis.202005013

- Abstract:

- In order to solve the problems of subjectivity and objectivity in feature extraction of stainless steel weld defects, an AlexNet convolutional neural network model based on transfer learning is proposed for automatic classification of stainless steel weld defects. First, due to the lack of stainless steel weld defect data, the first three layers of the network are frozen by transfer learning, which reduces the requirement of the network on the input data. In order to speed up the convergence of the network, the batch normalization (BN) of the feature information extracted from the two latter layers of convolution is carried out. The LeakyReLU function is used to activate the features in the negative interval so as to improve the robustness of the model and the ability of feature extraction. The results show that the accuracy of the model is 95.12%, and the recognition accuracy is 9.8% higher than that of the original structure. It has been verified that the improved method can classify five kinds of stainless steel weld defects such as crack, blowhole, slag inclusion, incomplete fusion, and incomplete penetration with high precision. Compared to the existing methods, this method has a wider recognition area, higher accuracy, and certain engineering significance.

- References:

-

[1] MUNIR N, KIM H J, PARK J, et al. Convolutional neural network for ultrasonic weldment flaw classification in noisy conditions[J]. Ultrasonics, 2019, 94:74-81.

[2] 蔡晓龙. 基于支持向量机的焊缝缺陷建模及其识别算法研究[D]. 西安:西安石油大学, 2014:1-75.

CAI Xiaolong. Welding defects modeling and recognition algorithm reasearching based on Support Vector Machine[D]. Xi’an:Xi’an Shiyou University, 2014:1-75.

[3] FAN Junfeng, JING Fengshui, FANG Zaojun, et al. Automatic recognition system of welding seam type based on SVM method[J]. The international journal of advanced manufacturing technology, 2017, 92(1/2/3/4):989-999.

[4] CHEN Yuan, MA Hongwei, DONG Ming. Automatic classification of welding defects from ultrasonic signals using an SVM-based RBF neural network approach[J]. Insight-non-destructive testing and condition monitoring, 2018, 60(4):194-199.

[5] 刘梦溪, 巨永锋, 高炜欣, 等. 焊缝缺陷图像分类识别的深度置信网络研究[J]. 测控技术, 2018, 37(8):5-9, 15

LIU Mengxi, JU Yongfeng, GAO Weixin, et al. Research on deep belief network for images classification and recognition of weld defects[J]. Measurement & control technology, 2018, 37(8):5-9, 15

[6] WANG Xiaokai, GUAN Shanyue, HUA Lin, et al. Classification of spot-welded joint strength using ultrasonic signal time-frequency features and PSO-SVM method[J]. Ultrasonics, 2019, 91:161-169.

[7] 侯怀书, 任慧霞. 金属管道对接焊缝超声检测缺陷类型识别研究[J]. 热加工工艺, 2019, 48(21):143-146, 152

HOU Huaishu, REN Huixia. Research on defect type recognition of metal pipeline butt weld by ultrasound detection[J]. Hot working technology, 2019, 48(21):143-146, 152

[8] WAIBEL A. Modular construction of time-delay neural networks for speech recognition[J]. Neuralcomput, 1989, 1:39-46.

[9] KRIZHEVSKY A, SUTSKEVER I, HINTON G E. ImageNet classification with deep convolutional neural networks[J]. Communications of the ACM, 2017, 60(6):84-90.

[10] 刘思洋, 黄坚, 刘桂雄, 等. AlexNet两光照下多类别法定货币识别技术[J]. 中国测试, 2019, 45(9):118-122

LIU Siyang, HUANG Jian, LIU Guixiong, et al. Technology of multi-category legal currency identification under multi-light conditions based on AlexNet[J]. China measurement & test, 2019, 45(9):118-122

[11] 张根保, 李浩, 冉琰, 等. 一种用于轴承故障诊断的迁移学习模型[J]. 吉林大学学报(工学版), 2020, 50(5):1617-1626

ZHANG Genbao, LI Hao, RAN Yan, et al. A transfer learning model for bearing fault diagnosis[J]. Journal of Jilin University (engineering and technology edition), 2020, 50(5):1617-1626

[12] IOFFE S, SZEGEDY C. Batch normalization:accelerating deep network training by reducing internal covariate shif[C]//Proceedings of the 32nd International Conference on International Conference on Machine Learning. Lille, France, 2015:448-456.

[13] JIANG Xianwei, CHANG Liang, ZHANG Yudong. Classification of alzheimer’s disease via eight-layer convolutional neural network with batch normalization and dropout techniques[J]. Journal of medical imaging and health informatics, 2020, 10(5):1040-1048.

[14] 陈波, 张华, 王姮, 等. 基于迁移学习的坝面表观缺陷智能检测方法研究[J]. 水利水电技术, 2020, 51(4):106-112

CHEN Bo, ZHANG Hua, WANG Heng, et al. Transfer learning-based study on method of intelligent detection of dam surface apparent defect[J]. Water resources and hydropower engineering, 2020, 51(4):106-112

[15] 龚震霆, 陈光喜, 曹建收. 卷积神经网络在脑脊液图像分类上的应用[J]. 计算机工程与设计, 2017, 38(4):1056-1061

GONG Zhenting, CHEN Guangxi, CAO Jianshou. Cerebrospinal fluid images classification based on convolution neural network[J]. Computer engineering and design, 2017, 38(4):1056-1061

[16] 戎辉, 华一丁, 张小俊, 等. 基于迁移学习和AlexNet的驾驶员行为状态识别方法[J]. 科学技术与工程, 2019, 19(28):208-216

RONG Hui, HUA Yiding, ZHANG Xiaojun, et al. Driver behavior recognition method based on migration learning and AlexNet[J]. Science technology and engineering, 2019, 19(28):208-216

[17] 周奇才, 刘星辰, 赵炯, 等. 旋转机械一维深度卷积神经网络故障诊断研究[J]. 振动与冲击, 2018, 37(23):31-37

ZHOU Qicai, LIU Xingchen, ZHAO Jiong, et al. Fault diagnosis for rotating machinery based on 1D depth convolutional neural network[J]. Journal of vibration and shock, 2018, 37(23):31-37

[18] 张安安, 黄晋英, 冀树伟, 等. 基于卷积神经网络图像分类的轴承故障模式识别[J]. 振动与冲击, 2020, 39(4):165-171

ZHANG An’an, HUANG Jinying, JI Shuwei, et al. Bearing fault pattern recognition based on image classification with CNN[J]. Journal of vibration and shock, 2020, 39(4):165-171

[19] 白林, 魏昕, 刘禹, 等. 基于VGG模型的岩石薄片图像识别[J]. 地质通报, 2019, 38(12):2053-2058

BAI Lin, WEI Xin, LIU Yu, et al. Rock thin section image recognition and classification based on VGG model[J]. Geological bulletin of China, 2019, 38(12):2053-2058

[20] 詹翔, 张婷, 林聪, 等. 基于深度学习的乳腺病理图像分类实验方法[J]. 计算机应用, 2019, 39(S2):118-121

ZHAN Xiang, ZHANG Ting, LIN Cong, et al. Classification method of breast pathological images based on deep learning[J]. Journal of computer applications, 2019, 39(S2):118-121

- Similar References:

Memo

-

Last Update:

2021-06-25