[1]WANG Wei,ZHOU Xinzhi.Temperature-sectioned prediction model for microwave heating process based on adaptive network-based fuzzy inference system[J].CAAI Transactions on Intelligent Systems,2016,11(1):61-69.[doi:10.11992/tis.201501028]

Copy

Temperature-sectioned prediction model for microwave heating process based on adaptive network-based fuzzy inference system

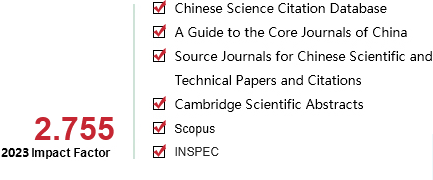

CAAI Transactions on Intelligent Systems[ISSN 1673-4785/CN 23-1538/TP] Volume:

11

Number of periods:

2016 1

Page number:

61-69

Column:

学术论文—智能系统

Public date:

2016-02-25

- Title:

- Temperature-sectioned prediction model for microwave heating process based on adaptive network-based fuzzy inference system

- Keywords:

- microwave heating process; sectioned temperature prediction; K-means clustering; adaptive Neuro-Fuzzy inference system; BP nerve network; subtraction clustering

- CLC:

- TP18;TP301.6

- DOI:

- 10.11992/tis.201501028

- Abstract:

- During the microwave heating process, materials in different temperature regions have different internal characteristics. Using traditional temperature forecasting methods, it is difficult to obtain satisfactory prediction results for both low-and high-temperature sections in a medium. To solve this problem, this study proposes a new temperature-sectioned forecasting model based on the ANFIS (adaptive neuro-fuzzy inference system). For this method, we established a temperature-division mechanism based on K-means clustering. Additionally, we used an ANFIS with different structures to forecast the temperature of the heated medium at different stages. We also constructed a conventional ANFIS to predict a material’s low temperature and a subtraction-clustering ANFIS that determines the fuzzy rules from data to predict a material’s high temperature. Simulation results demonstrate that the proposed method achieves satisfactory results for both low-and high-temperature sections when compared to ANFISs and BP(back propagation) networks with a single structure. Model efficiency can reach 97.41% and the prediction accuracy is significantly improved. The proposed model can improve the efficiency and safety of the microwave heating process.

- References:

-

[1] 刘长军, 申东雨. 微波加热陶瓷中热失控现象的分析与控制[J]. 中国科学E辑:技术科学, 2008, 38(7):1097-1105.LIU Changjun, SHEN Dongyu. Analysis and control of the thermal runaway of ceramic slab underheating ceramics[J]. Science in China series e:technological science, 2008, 51(12):2233-2241.

[2] SANDER A, BOLF N, PRLI?-KARDUM J. Research on dynamics and drying time in microwave paper drying[J]. Chemical and biochemical engineering quarterly, 2003, 17(2):159-164.

[3] WEI W, YIN H M, TANG J M. An optimal control problem for microwave heating[J]. Nonlinear analysis:theory, methods & applications, 2012, 75(4):2024-2036.

[4] PEDREÑO-MOLINA J L, MONZÓ-CABRERA J, TOLEDO-MOREO A, et al. A novel predictive architecture for microwave-assisted drying processes based on neural networks[J]. International communications in heat and mass transfer, 2005, 32(8):1026-1033.

[5] TRIPATHY P P, KUMAR S. Neural network approach for food temperature prediction during solar drying[J]. International journal of thermal sciences, 2009, 48(7):1452-1459.

[6] 王安娜, 陶子玉, 姜茂发, 等. 基于PSO和BP网络的LF炉钢水温度智能预测[J]. 控制与决策, 2006, 21(7):814-816, 820. WANG Anna, TAO Ziyu, JIANG Maofa, et al. Intelligence temperature prediction of molten steel in LF based on PSO combined with BP neural network[J]. Control and decision, 2006, 21(7):814-816, 820.

[7] 崔桂梅, 李静, 张勇, 等. 基于T-S模糊神经网络模型的高炉铁水温度预测建模[J]. 钢铁, 2013, 48(11):11-15. CUI Guimei, LI Jing, ZHANG Yong, et al. Prediction modeling study for blast furnace hot metal temperature based on T-S fuzzy neural network model[J]. Iron and steel, 2013, 48(11):11-15.

[8] DONOHO D L. De-noising by soft-thresholding[J]. IEEE transactions on information theory, 1995, 41(3):613-627.

[9] 陶珂, 朱建军. 小波去噪质量评价方法的对比研究[J]. 大地测量与地球动力学, 2012, 32(2):128-133. TAO Ke, ZHU Jianjun. A comparative study on validity assessment of wavelet De-noising[J]. Journal of geodesy and geodynamics, 2012, 32(2):128-133.

[10] 茹斌, 张天伟, 王宇欣. 基于小波去噪及ARMA模型的故障率预测方法研究[J]. 测控技术, 2014, 33(10):43-46, 50. RU Bin, ZHANG Tianwei, WANG Yuxin. Research on the method of failure rate prediction based on wavelet and ARMA model[J]. Measurement & control technology, 2014, 33(10):43-46, 50.

[11] JANG J S R. ANFIS:Adaptive-network-based fuzzy inference system[J]. IEEE transactions on systems, man and cybernetics, 1993, 23(3):665-685.

[12] TAKAGI T, SUGENO M. Fuzzy identification of systems and its applications to modeling and control[J]. IEEE Transactions on systems, man and cybernetics, 1995, SMC-15(1):116-132.

[13] NAYAK P C, SUDHEER K P. Fuzzy model identification based on cluster estimation for reservoir inflow forecasting[J]. Hydrological processes, 2008, 22(6):827-841.

[14] MIRRASHID M. Earthquake magnitude prediction by adaptive neuro-fuzzy inference system (ANFIS) based on fuzzy C-means algorithm[J]. Nature hazards, 2014, 74(3):1577-1593.

[15] Al-MAYYAHI A, WANG W, BIRCH P. Adaptive neuro-fuzzy technique for autonomous ground vehicle navigation[J]. Robotics, 2014, 3(4):349-370.

[16] HIDAYAT, PRAMONOHADI S, SARJIYA, et al. A comparative study of PID, ANFIS and hybrid PID-ANFIS controllers for speed control of Brushless DC Motor drive[C]//Proceedings of International Conference on Computer, Control, Informatics and Its Applications (IC3INA). Jakarta, Indonesia, 2013:117-122.

[17] 蒋浩宇, 富立, 范耀祖. ANFIS在车辆导航系统信息融合中应用的仿真研究[J]. 系统仿真学报, 2006, 18(4):1051-1054. JIANG Haoyu, FU Li, FAN Yaozu. Simulation study on application of ANFIS for information fusion of vehicle navigation system[J]. Journal of system simulation, 2006, 18(4):1051-1054.

[18] 夏琳琳, 苗贵娟, 初妍, 等. 基于自适应神经模糊系统的足球机器人射门点的确定[J]. 智能系统学报, 2013, 8(2):143-148.XIA Linlin, MIAO Guijuan, CHU Yan, et al. Determination of shooting point for soccer robot based upon adaptive neuro-fuzzy in ference system[J]. CAAI transactions on intelligent systems, 2013, 8(2):143-148.

[19] 张秀玲, 逄宗鹏, 李少清, 等. ANFIS的板形控制动态影响矩阵方法[J]. 智能系统学报, 2010, 5(4):360-365. ZHANG Xiuling, PANG Zongpeng, LI Shaoqing, et al. A dynamic influence matrix method for flatness control based on adaptive-network-based fuzzy inference systems[J]. CAAI transactions on intelligent systems, 2010, 5(4):360-365.

[20] YU Xiaohu, CHEN guoan. Efficient backpropagation learning using optimal learning rate and momentum[J]. Neural networks, 1997, 10(3):517-527.

[21] 蒋静芝, 孟相如, 李欢, 等. 减法聚类-ANFIS在网络故障诊断的应用研究[J]. 计算机工程与应用, 2011, 47(8):76-78, 86. JIANG Jingzhi, MENG Xiangru, LI Huan, et al. Study on application of subtractive clustering and adaptive network-based fuzzy inference system in network fault diagnosis[J]. Computer engineering and applications, 2011, 47(8):76-78, 86.

[22] PLATON R, AMAZOUZ M. Modeling of a drying process using subtractive clustering based system identification[C]//Proceedings of the Joint 9th IFSA World Congress and 20th NAFIPS International Conference. Vancouver, BC, Canada, 2001:2994-2999.

[23] 王增福, 潘泉, 郎林, 等. 基于减法聚类的动态航迹聚类算法[J]. 系统仿真学报, 2009, 21(16):5240-5243, 5246. WANG Zengfu, PAN Quan, LANG Lin, et al. Dynamic track cluster algorithm based on subtractive clustering[J]. Journal of system simulation, 2009, 21(6):5240-5243, 5246.

[24] 朱广宇, 刘克, 乔梁. 基于T-S模型的交通状态自适应神经模糊推理系统建模与仿真[J]. 北京交通大学学报, 2012, 36(6):96-101. ZHU Guangyu, LIU Ke, QIAO Liang. Modeling and simulation for traffic states with ANFIS based on T-S model[J]. Journal of Beijing jiaotong University, 2012, 36(6):96-101.

[25] 张智星, 孙春在,[日]水谷英二. 神经-模糊和软计算[M]. 西安:西安交通大学出版社, 2000:346-401. ZHANG Zhixing, SUN Chunzai, MIZUTANI E. Neuro-fuzzy and soft computing[M]. Xi’an:Prentice Hall, 2000:346-401.

[26] 李国勇, 杨丽娟. 神经·模糊·预测控制及其MATLAB实现[M]. 3版. 北京:电子工业出版社, 2013:305-379. LI Guoyong, YANG Lijuan. Neural-fuzzy-predictive control and the realization by MATLAB[M]. 3rd ed. Beijing:Publishing House of Electronics Industry, 2013:305-379.

- Similar References:

Memo

-

Last Update:

1900-01-01