[1]ZHANG Xiu-ling,CHEN Li-jie,PANG Zong-peng,et al.A predictive system for process control of flatness in rolling mills using a radial basis function network[J].CAAI Transactions on Intelligent Systems,2010,5(1):70-73.

Copy

A predictive system for process control of flatness in rolling mills using a radial basis function network

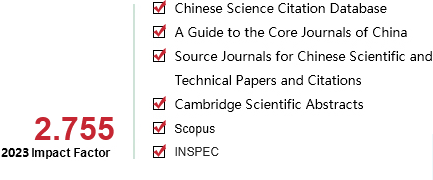

CAAI Transactions on Intelligent Systems[ISSN 1673-4785/CN 23-1538/TP] Volume:

5

Number of periods:

2010 1

Page number:

70-73

Column:

学术论文—机器学习

Public date:

2010-02-25

- Title:

- A predictive system for process control of flatness in rolling mills using a radial basis function network

- Keywords:

- shape control; HCmill; hydraulic control of bending rollers; RBF neural network; predictive control

- CLC:

- TP18

- DOI:

- -

- Abstract:

- When plate and strip rolling is done in very complex environments, such as high crown (HC) rolling mills, there are many factors that make system control difficult. Factors affecting the flatness of steel sheets include temperature changes as well as nonlinearities that lead to uncertainty about results from bending roller forces. A novel predictive control program was proposed, one employing a radial basis function (RBF) neural network. It ensures flatness by controlling the bending forces of rollers. Simulation results confirmed this scheme has good performance and robustness.

- References:

-

[1]宗晓萍,冯贺平. 基于神经网络的时滞系统预测控制[J]. 控制理论与应用, 2005, 24(12): 68.

ZONG Xiaoping, FENG heping. Neural networkbased predictive control for timedelay systems[J]. Control Theory and Application, 2005, 24(12): 68.

[2]HARTER F P, De CAMPOS VELHO H F. New approach to applying neural network in nonlinear dynamic model[J]. Applied Mathematical Modelling, 2008, 32(12): 26212633.

[3]CHOI J N, OH S K, PEDRYCZ W. Identification of fuzzy models using a successive tuning method with a variant identification ratio[J]. Fuzzy Sets and Systems, 2008, 159(21): 28732889.

[4]邓继雄,李志舜,梁 红.确定神经网络参数的新方法[J]. 微处理机, 2006, 27(4): 4849.

DENG Jixiong, LI Zhishun, LIANG Hong.A new method of ascertaining radial basis function network parameter[J]. Microprocessors, 2006, 27(4): 4849.

[5]张秀玲.冷带轧机板形智能识别与智能控制研究[D]. 秦皇岛: 燕山大学, 2002.

ZHANG Xiuling. Research on intelligent control and recognition of flatness for cold strip mill[D]. Qinhuangdao: Yanshan University, 2002.

[6]连家创,刘宏民. 板形板厚控制[M]. 北京: 兵器工业出版社, 1996.

[7]张秀玲,刘宏民.神经网络模型参考自适应控制及其在带材板形控制系统中的应用[J].机械工程学报, 2001, 37(9): 8387.

ZHANG Xiuling, LIU Hongmin. Neural network model reference adaptive control and its application in the strip shape control system[J]. Chinese Journal of Mechanical Engineering, 2001, 37(9): 8387.

[8]陆冬娜,杨马英. 基于RBF神经网络的非线性模型预测控制[J]. 浙江工业大学学报, 2007, 35(2): 123126.

LU Dongna, YANG Maying. Nonlinear model predictive control based on RBF networks[J]. Journal of Zhejiang University of Technology, 2007, 35(2): 123126.

- Similar References:

Memo

-

Last Update:

2010-04-06