[1]ZHAO Zhenbing,WANG Rui,WANG Yiheng,et al.Bolt defect recognition method for transmission line based on joint structure-semantic relationship graph knowledge reasoning[J].CAAI Transactions on Intelligent Systems,2024,19(6):1584-1592.[doi:10.11992/tis.202305050]

Copy

Bolt defect recognition method for transmission line based on joint structure-semantic relationship graph knowledge reasoning

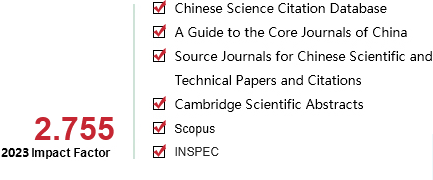

CAAI Transactions on Intelligent Systems[ISSN 1673-4785/CN 23-1538/TP] Volume:

19

Number of periods:

2024 6

Page number:

1584-1592

Column:

人工智能院长论坛

Public date:

2024-11-05

- Title:

- Bolt defect recognition method for transmission line based on joint structure-semantic relationship graph knowledge reasoning

- Keywords:

- transmission lines; bolts; defects recognition; knowledge representation; knowledge reasoning; graph neural networks; structural relationships; semantic relationships

- CLC:

- TP18

- DOI:

- 10.11992/tis.202305050

- Abstract:

- To tackle the issues of visual inseparability and semantic ambiguity in identifying transmission line bolt defects, a new method using joint structure–semantic relationship graph knowledge reasoning is proposed. Initially, a semantic expression module extracts feature class mappings that highlight the discriminative attributes of each bolt. Subsequently, the structural relationship graph captures contextual bolt information and establishes spatial relationships across different scales. Utilizing a graph convolutional neural network and cooperative learning, the semantic relation graph nodes are updated with structural and semantic knowledge derived from the bolt attributes. Finally, the network employs label co-occurrence information from the bolt training data set to improve the accuracy of defect recognition. In the experimental stage, 13 types of bolt properties across 3 types of typical fittings were examined. Comparative experiments show that the method proposed in this study outperforms other methods in identifying bolt defects, boosting accuracy by 8.12% over the baseline model.

- References:

-

[1] 周远翔, 陈健宁, 张灵, 等. “双碳” 与“新基建” 背景下特高压输电技术的发展机遇[J]. 高电压技术, 2021, 47(7): 2396-2408.

ZHOU Yuanxiang, CHEN Jianning, ZHANG Ling, et al. Opportunity for developing ultra high voltage transmission technology under the emission peak, carbon neutrality and new infrastructure[J]. High voltage engineering, 2021, 47(7): 2396-2408.

[2] SUMAGAYAN M U, PREMACHANDRA C, MANGORSI R B, et al. Detecting power lines using point instance network for distribution line inspection[J]. IEEE access, 2021, 9: 107998-108008.

[3] 傅博, 姜勇, 王洪光, 等. 输电线路巡检图像智能诊断系统[J]. 智能系统学报, 2016, 11(1): 70-77.

FU Bo, JIANG Yong, WANG Hongguang, et al. Intelligent diagnosis system for patrol check images of power transmission lines[J]. CAAI transactions on intelligent systems, 2016, 11(1): 70-77.

[4] MAO Tianqi, HUANG Kai, ZENG Xianwu, et al. Development of power transmission line defects diagnosis system for UAV inspection based on binocular depth imaging technology[C]//2019 2nd International Conference on Electrical Materials and Power Equipment. Guangzhou: IEEE, 2019: 478-481.

[5] 赵振兵, 张帅, 蒋炜, 等. 基于DBSCAN-FPN的输电线路螺栓缺销检测方法[J]. 中国电力, 2021, 54(3): 45-54.

ZHAO Zhenbing, ZHANG Shuai, JIANG Wei, et al. Detection method for bolts with mission pins on transmission lines based on DBSCAN-FPN[J]. Electric power, 2021, 54(3): 45-54.

[6] ZHAO Zhenbing, QI Hongyu, QI Yincheng, et al. Detection method based on automatic visual shape clustering for pin-missing defect in transmission lines[J]. IEEE transactions on instrumentation and measurement, 2020, 69(9): 6080-6091.

[7] HE Hui, LI Yuchen, YANG Jing, et al. Pin-missing defect recognition based on feature fusion and spatial attention mechanism[J]. Energy reports, 2022, 8: 656-663.

[8] WANG Hongchao, SHAO Yunfeng, ZOU Suli, et al. Detection of cotter pins missing of connection fittings on transmission lines of power system[C]//2021 40th Chinese Control Conference. Shanghai: IEEE, 2021: 6873-6879.

[9] LIN Z, LIANG Y, JIANG Q. A bolt defect recognition algorithm based on attention model[C]//Proceedings of the 7th International Conference on Fuzzy Systems and Data Mining. Seoul: IOS, 2021: 86-93.

[10] 张珂, 何颖宣, 赵凯, 等. 可变形NTS-Net的螺栓属性多标签分类[J]. 中国图象图形学报, 2021, 26(11): 2582-2593.

ZHANG Ke, HE Yingxuan, ZHAO Kai, et al. Multi-label classification method of bolt attributes based on deformable NTS-Net[J]. Journal of image and graphics, 2021, 26(11): 2582-2593.

[11] ZHAO Zhenbing, WANG Rui, LI Yanxu, et al. A new multilabel recognition framework for transmission lines bolt defects based on the combination of semantic knowledge and structural knowledge[J]. IEEE transactions on instrumentation and measurement, 2022, 71: 5020211.

[12] 赵振兵, 王睿, 赵文清, 等. 基于图知识推理的输电线路缺销螺栓识别方法[J]. 智能系统学报, 2023, 18(2): 372-380.

ZHAO Zhenbing, WANG Rui, ZHAO Wenqing, et al. Pin-missing bolts recognition method for transmission lines based on graph knowledge reasoning[J]. CAAI transactions on intelligent systems, 2023, 18(2): 372-380.

[13] HE Kaiming, ZHANG Xiangyu, REN Shaoqing, et al. Deep residual learning for image recognition[C]//2016 IEEE Conference on Computer Vision and Pattern Recognition. Las Vegas: IEEE, 2016: 770-778.

[14] 赵强, 左石. 输电线路金具理论与应用[M]. 北京: 中国电力出版社, 2013: 2-12.

[15] OGUZ YAZICI V, GONZALEZ-GARCIA A, RAMISA A, et al. Orderless recurrent models for multi-label classification[C]//2020 IEEE/CVF Conference on Computer Vision and Pattern Recognition. Seattle: IEEE, 2020: 13437-13446.

[16] KE Xiao, LIU Tongan, LI Zhenda. Human attribute recognition method based on pose estimation and multiple-feature fusion[J]. Signal, image and video processing, 2020, 14(7): 1441-1449.

[17] ZHOU Feng, HUANG Sheng, XING Yun. Deep semantic dictionary learning for multi-label image classification[EB/OL]. (2020-12-23)[2021-12-01]. https://arxiv.orglabs/2012.12509.

[18] CHEN Zhaomin, WEI Xiushen, WANG Peng, et al. Multi-label image recognition with graph convolutional networks[C]//2019 IEEE/CVF Conference on Computer Vision and Pattern Recognition. Long Beach: IEEE, 2019: 5172-5181.

[19] GAO Binbin, ZHOU Hongyu. Learning to discover multi-class attentional regions for multi-label image recognition[J]. IEEE transactions on image processing: a publication of the IEEE signal processing society, 2021, 30: 5920-5932.

[20] NGUYEN H D, VU X S, LE D T. Modular graph transformer networks for multi-label image classification[C]// Proceedings of the AAAI Conference on Artificial Intelligence. Vancouver: Association for the Advancement of Artificial Intelligence, 2021: 9092-9100.

[21] FU Kui, LI Jia, MA Lin, et al. Intrinsic relationship reasoning for small object detection[EB/OL]. (2020-09-02)[2021-01-01]. https://arxiv.org/abs/2009.00833.

[22] ZHAO Jiawei, YAN Ke, ZHAO Yifan, et al. Transformer-based dual relation graph for multi-label image recognition[C]//2021 IEEE/CVF International Conference on Computer Vision. Montreal: IEEE, 2021: 163-172.

[23] YE Jin, HE Junjun, PENG Xiaojiang, et al. Attention-driven dynamic graph convolutional network for multi-label image recognition[C]//European Conference on Computer Vision. Cham: Springer, 2020: 649-665.

[24] LIU Yong, WANG Ruiping, SHAN Shiguang, et al. Structure inference net: object detection using scene-level context and instance-level relationships[C]//2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition. Salt Lake City: IEEE, 2018: 6985-6994.

[25] 翟永杰, 杨旭, 赵振兵, 等. 融合共现推理的Faster R-CNN输电线路金具检测[J]. 智能系统学报, 2021, 16(2): 237-246.

ZHAI Yongjie, YANG Xu, ZHAO Zhenbing, et al. Integrating co-occurrence reasoning for Faster R-CNN transmission line fitting detection[J]. CAAI transactions on intelligent systems, 2021, 16(2): 237-246.

[26] KIPF T N, WELLING M. Semi-supervised classification with graph convolutional networks[EB/OL]. (2016-09-09)[2021-01-01]. https://arxiv.org/abs/1609.02907.

- Similar References:

Memo

-

Last Update:

2024-11-05