[1]MOU Jianpeng,LIU Wentao,XIONG Weili.Industrial process fault detection based on bidirectional generative adversarial networks[J].CAAI Transactions on Intelligent Systems,2024,19(5):1199-1208.[doi:10.11992/tis.202306011]

Copy

Industrial process fault detection based on bidirectional generative adversarial networks

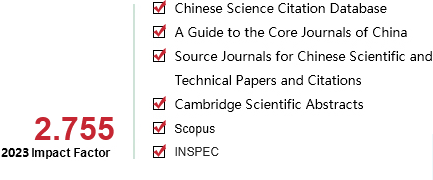

CAAI Transactions on Intelligent Systems[ISSN 1673-4785/CN 23-1538/TP] Volume:

19

Number of periods:

2024 5

Page number:

1199-1208

Column:

学术论文—智能系统

Public date:

2024-09-05

- Title:

- Industrial process fault detection based on bidirectional generative adversarial networks

- Keywords:

- fault detection; generative adversarial networks; long short-term memory network; autoencoders; reconstruction error; time series; TE process; coal pulverization process

- CLC:

- TP277

- DOI:

- 10.11992/tis.202306011

- Abstract:

- The standard bidirectional generative adversarial network (BiGAN) model structure consists of a fully connected layer and only considers the process characteristics of a single sample for statistical construction during fault detection. Therefore, an improved bidirectional generative adversarial network for industrial process fault detection is proposed. The method preprocesses the samples using a denoising autoencoder and constructs the reconstruction error as the input for the BiGAN. This approach reduces the masking of abnormal information by normal information in abnormal samples and enhances the ability of the model to detect small faults. Additionally, a long short-term codec is introduced into the BiGAN model, which enables the generator to focus on both the current process characteristics and the correlation between historical samples while generating false samples. This improves the ability of the model to detect time-series data. The proposed fault detection method was applied to the Tennessee Eastman process and an actual coal mill industrial process. This method improved the alarm rate while maintaining a low false alarm rate, which demonstrates good generalization performance.

- References:

-

[1] YIN Shen, YANG Xuebo, KARIMI H R. Data-driven adaptive observer for fault diagnosis[J]. Mathematical problems in engineering, 2012(1): 832-836.

[2] GE Zhiqiang. Review on data-driven modeling and monitoring for plant-wide industrial processes[J]. Chemometrics and intelligent laboratory systems, 2017, 171: 16-25.

[3] JIANG Qingchao, YAN Xuefeng, HUANG Biao. Performance-driven distributed PCA process monitoring based on fault-relevant variable selection and Bayesian inference[J]. IEEE transactions on industrial electronics, 2016, 63(1): 377-386.

[4] YU Gang. Fault feature extraction using independent component analysis with reference and its application on fault diagnosis of rotating machinery[J]. Neural computing and applications, 2015, 26(1): 187-198.

[5] ZHONG Bin, WANG Jing, ZHOU Jinglin, et al. Quality-related statistical process monitoring method based on global and local partial least-squares projection[J]. Industrial & engineering chemistry research, 2016, 55(6): 1609-1622.

[6] LEE J M, YOO C, CHOI S W, et al. Nonlinear process monitoring using kernel principal component analysis[J]. Chemical engineering science, 2004, 59(1): 223-234.

[7] WANG Kai, CHEN J, SONG Zhihuan. Performance analysis of dynamic PCA for closed-loop process monitoring and its improvement by output oversampling scheme[J]. IEEE transactions on control systems technology, 2019, 27(1): 378-385.

[8] DEWI Y N, RIANA D, MANTORO T. Improving Na?ve Bayes performance in single image pap smear using weighted principal component analysis[C]//2017 International Conference on Computing, Engineering, and Design. Kuala Lumpur: IEEE, 2017: 1-5.

[9] KRIZHEVSKY A, SUTSKEVER I, HINTON G E. ImageNet classification with deep convolutional neural networks[J]. Communications of the ACM, 2017, 60(6): 84-90.

[10] SARATH C A P, LAULY S, LAROCHELLE H, et al. An autoencoder approach to learning bilingual word representations[J]. Advances in neural information processing systems, 2014, 3: 1853-1861.

[11] GOODFELLOW I J, POUGET J, MIRZA M, et al. Generative adversarial networks[J]. Advances in neural information processing systems, 2014, 3: 2672-2680.

[12] 朱晓荣, 张佩佩. 基于GAN的异构无线网络故障检测与诊断算法[J]. 通信学报, 2020, 41(8): 110-119.

ZHU Xiaorong, ZHANG Peipei. Fault detection and diagnosis method for heterogeneous wireless network based on GAN[J]. Journal on communications, 2020, 41(8): 110-119.

[13] 郭俊锋, 王淼生, 孙磊, 等. 基于生成对抗网络的滚动轴承不平衡数据集故障诊断新方法[J]. 计算机集成制造系统, 2022, 28(9): 2825-2835.

GUO Junfeng, WANG Miaosheng, SUN Lei, et al. New method of fault diagnosis for rolling bearing imbalance data set based on generative adversarial network[J]. Computer integrated manufacturing systems, 2022, 28(9): 2825-2835.

[14] YANG Xin, FENG Dajun. Generative adversarial network based anomaly detection on the benchmark Tennessee Eastman process[C]//2019 5th International Conference on Control, Automation and Robotics. Beijing: IEEE, 2019: 644-648.

[15] PATIL R, BIRADAR R, RAVI V, et al. Network traffic anomaly detection using PCA and BiGAN[J]. Internet technology letters, 2022, 5(1): 1-6.

[16] KAPLAN M O, ALPTEKIN S E. An improved BiGAN based approach for anomaly detection[J]. Procedia computer science, 2020, 176: 185-194.

[17] HOCHREITER S, SCHMIDHUBER J. Long short-term memory[J]. Neural computation, 1997, 9(8): 1735-1780.

[18] YU Jianbo, LIU Xing, YE L. Convolutional long short-term memory autoencoder-based feature learning for fault detection in industrial processes[J]. IEEE transactions on instrumentation and measurement, 2021, 70: 1-15.

[19] PARK P, DI MARCO P, SHIN H, et al. Fault detection and diagnosis using combined autoencoder and long short-term memory network[J]. Sensors, 2019, 19(21): 4612.

[20] VINCENT D, ISHMAEL B, BEN P, et al. Adversarially learned inference. (2016-06-02)[2023-06-07]. https://arxiv.org/abs/1606.00704.

[21] 潘丙翱. 基于自编码器的高维时间序列异常检测[D]. 杭州: 浙江大学, 2021.

PAN Bing’ao. Journal of chemical engineering anomaly detection of high-dimensional time series based on self-coder[D]. Hangzhou: Zhejiang University, 2021.

[22] GE Zhiqiang, SONG Zhihuan. Distributed PCA model for plant-wide process monitoring[J]. Industrial & engineering chemistry research, 2013, 52(5): 1947-1957.

[23] 宋励嘉, 童楚东. 基于缺失变量估计误差的工业过程监测方法[J]. 高校化学工程学报, 2019, 33(1): 167-173.

SONG Lijia, TONG Chudong. Industrial process monitoring based on estimation error of missing variables[J]. Journal of chemical engineering of Chinese universities, 2019, 33(1): 167-173.

[24] 吴晓东, 熊伟丽. 采用编码输入的生成对抗网络故障检测方法及应用[J]. 智能系统学报, 2022, 17(3): 496-505.

WU Xiaodong, XIONG Weili. Fault detection method and its application using GAN with an encoded input[J]. CAAI transactions on intelligent systems, 2022, 17(3): 496-505.

[25] AUDIBERT J, MICHIARDI P, GUYARD F, et al. USAD: UnSupervised anomaly detection on multivariate time series[C]//Proceedings of the 26th ACM SIGKDD International Conference on Knowledge Discovery & Data Mining. Virtual Event: ACM, 2020: 23-27.

- Similar References:

Memo

-

Last Update:

2024-09-05