[1]HAN Zhonghua,LI Kaijia,ZHOU Xiaofeng,et al.Research on the optimization of flexible flow shop scheduling based on deep learning[J].CAAI Transactions on Intelligent Systems,2023,18(3):468-479.[doi:10.11992/tis.202112028]

Copy

Research on the optimization of flexible flow shop scheduling based on deep learning

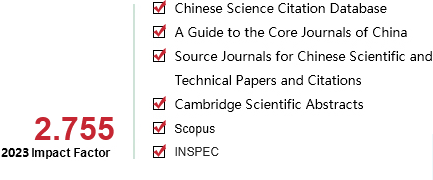

CAAI Transactions on Intelligent Systems[ISSN 1673-4785/CN 23-1538/TP] Volume:

18

Number of periods:

2023 3

Page number:

468-479

Column:

学术论文—机器学习

Public date:

2023-07-05

- Title:

- Research on the optimization of flexible flow shop scheduling based on deep learning

- Keywords:

- deep learning; production scheduling optimization; processing on-line sequence; flexible flow shop; gated recurrent unit; sequence-to-sequence; attention mechanism; historical production data

- CLC:

- TP183

- DOI:

- 10.11992/tis.202112028

- Abstract:

- The global optimization algorithm for solving the production scheduling optimization problem of the flexible flow shops often adopts the group evolution algorithm or the mathematical programming algorithm. In the process of scheduling and optimizing new production tasks, these optimization methods need to perform time-consuming iterative optimization calculations again every time. Therefore, an intelligent scheduling optimization method based on deep learning is proposed to solve above problem. Through historical production data training, a sequence-to-sequence (Seq2Seq) deep learning model based on gated recurrent unit (GRU) is used to focus on the correlation between the production task information and process information in the scheduling data and the scheduling results. And further this correlation is used as the input of the model encoder; and the output of the model decoder is the on-line sequence of the workpiece. According to the on-line sequence, effective scheduling results can be quickly given, and the accuracy and speed of optimization can be further improved by introducing an attention mechanism. The results of simulation experiment show that the flexible flow shop scheduling optimization method based on deep learning can quickly obtain better scheduling optimization results.

- References:

-

[1] KHAMSEH A, JOLAI F, BABAEI M. Integrating sequence-dependent group scheduling problem and preventive maintenance in flexible flow shops[J]. The international journal of advanced manufacturing technology, 2015, 77(1): 173–185.

[2] GERSTL E, MOSHEIOV G, SARIG A. Batch scheduling in A two-stage flexible flow shop problem[J]. Foundations of computing and decision sciences, 2014, 39(1): 3–16.

[3] 王玉芳, 缪昇, 马铭阳, 等. 改进混合遗传算法的作业车间调度研究[J]. 现代制造工程, 2021(5): 32–38

WANG Yufang, MIAO Sheng, MA Mingyang, et al. Research on job shop scheduling based on improved hybrid genetic algorithm[J]. Modern manufacturing engineering, 2021(5): 32–38

[4] 孟磊磊, 张彪, 任亚平, 等. 求解分布式柔性作业车间调度的混合蛙跳算法[J/OL]. 机械工程学报: 1?10.[2021?07?11]. http://kns.cnki.net/kcms/detail/11.2187.th.20210608.1314.213.html.

MENG Leilei, ZHANG Biao, REN Yaping, et al. Hybrid leapfrog algorithm for distributed flexible job shop scheduling[J/OL]. Chinese journal of mechanical engineering: 1?10.[2021?07?11]. http://kns.cnki.net/kcms/detail/11.2187.th.20210608.1314.213.html.

[5] 李杨, 杨明顺, 陈曦, 等. 一种流水车间预测性维护与生产调度集成优化方法[J]. 机械科学与技术, 2022, 41(7): 1055–1061

LI Yang, YANG Mingshun, CHEN Xi, et al. Integrated optimization of predictive maintenance and production scheduling for flow-shop[J]. Mechanical science and technology for aerospace engineering, 2022, 41(7): 1055–1061

[6] 鲁华祥, 尹世远, 龚国良, 等. 基于深度确定性策略梯度的粒子群算法[J]. 电子科技大学学报, 2021, 50(2): 199–206

LU Huaxiang, YIN Shiyuan, GONG Guoliang, et al. A particle swarm optimization algorithm based on deep deterministic policy gradient[J]. Journal of University of Electronic Science and Technology of China, 2021, 50(2): 199–206

[7] 张强, 李盼池. 进化策略自主选择的改进混洗蛙跳算法[J]. 哈尔滨工程大学学报, 2019, 40(5): 979–985

ZHANG Qiang, LI Panchi. An improved shuffled frog leaping algorithm for the autonomous selection of evolutionary strategies[J]. Journal of Harbin Engineering University, 2019, 40(5): 979–985

[8] 王林, 吕盛祥, 曾宇容. 果蝇优化算法研究综述[J]. 控制与决策, 2017, 32(7): 1153–1162

WANG Lin, LYU Shengxiang, ZENG Yurong. Literature survey of fruit fly optimization algorithm[J]. Control and decision, 2017, 32(7): 1153–1162

[9] 张水平, 王碧, 陈阳. 基于逐层演化的群体智能算法优化[J]. 工程科学学报, 2017, 39(3): 462–473

ZHANG Shuiping, WANG Bi, CHEN Yang. Optimization for swarm intelligence based on layer-by-layer evolution[J]. Journal of university of science and technology Beijing, 2017, 39(3): 462–473

[10] LUO Shu, ZHANG Linxuan, FAN Yushun. Dynamic multi-objective scheduling for flexible job shop by deep reinforcement learning[J]. Computers & industrial engineering, 2021, 159: 107489.

[11] 朱泓睿, 元国军, 姚成吉, 等. 分布式深度学习训练网络综述[J]. 计算机研究与发展, 2021, 58(1): 98–115

ZHU Hongrui, YUAN Guojun, YAO Chengji, et al. Survey on network of distributed deep learning training[J]. Journal of computer research and development, 2021, 58(1): 98–115

[12] 陈伟宏, 安吉尧, 李仁发, 等. 深度学习认知计算综述[J]. 自动化学报, 2017, 43(11): 1886–1897

CHEN Weihong, AN Jiyao, LI Renfa, et al. Review on deep-learning-based cognitive computing[J]. Acta automatica sinica, 2017, 43(11): 1886–1897

[13] 吴秀丽, 孙琳. 智能制造系统基于数据驱动的车间实时调度[J]. 控制与决策, 2020, 35(3): 523–535

WU Xiuli, SUN Lin. Data-based real-time scheduling in smart manufacturing[J]. Control and decision, 2020, 35(3): 523–535

[14] 任剑锋, 叶春明. 嵌入指针网络的深度循环神经网络模型求解作业车间调度问题[J]. 计算机应用研究, 2021, 38(1): 120–124,128

REN Jianfeng, YE Chunming. Method to solve job-shop scheduling problem using deep recurrent neural network model with embedded pointer network[J]. Application research of computers, 2021, 38(1): 120–124,128

[15] 侯智, 陈进, 陈倩, 等. 面向不确定信息的神经网络完工期预测方法研究[J]. 机械设计与研究, 2017, 33(3): 116–119,130

HOU Zhi, CHEN Jin, CHEN Qian, et al. Predictive method of product due date toward uncertain information based on neural network[J]. Machine design & research, 2017, 33(3): 116–119,130

[16] 何军红, 马国伟, 刘赛, 等. MES柔性作业车间调度优化算法的研究[J]. 工业仪表与自动化装置, 2020(1): 26–32

HE Junhong, MA Guowei, LIU Sai, et al. Research on MES flexible job shop scheduling optimization algorithm[J]. Industrial instrumentation & automation, 2020(1): 26–32

[17] 游兰, 韩雪薇, 何正伟, 等. 基于改进Seq2Seq的短时AIS轨迹序列预测模型[J]. 计算机科学, 2020, 47(9): 169–174

YOU Lan, HAN Xuewei, HE Zhengwei, et al. Improved sequence-to-sequence model for short-term vessel trajectory prediction using AIS data streams[J]. Computer science, 2020, 47(9): 169–174

[18] 郑宗生, 刘敏, 胡晨雨, 等. 基于Seq2Seq和Attention的时序卫星云图台风等级预测[J]. 遥感信息, 2020, 35(4): 16–22

ZHENG Zongsheng, LIU Min, HU Chenyu, et al. Prediction of typhoon grade with time series typhoon satellite images based on Seq2Seq and attention[J]. Remote sensing information, 2020, 35(4): 16–22

[19] 吴俊杰, 刘冠男, 王静远, 等. 数据智能: 趋势与挑战[J]. 系统工程理论与实践, 2020, 40(08): 2116–2149

WU Junjie, LIU Guannan, WANG Jingyuan, et al. Data intelligence: trends and challenges[J]. Systems engineering theory and practice, 2020, 40(08): 2116–2149

[20] 王倩雯, 张延华, 付琼霄, 等. 基于双重注意力机制的降噪自编码器推荐算法[J]. 高技术通讯, 2020, 30(12): 1234–1242

WANG Qianwen, ZHANG Yanhua, FU Qiongxiao, et al. A denoising autoencoder algorithm for recommendation based on dual attention mechanism[J]. Chinese high technology letters, 2020, 30(12): 1234–1242

[21] 张津, 魏峰远, 冯凡, 等. 基于注意力机制和编码解码网络的遥感影像分类[J]. 测绘科学技术学报, 2020, 37(6): 610–615

ZHANG Jin, WEI Fengyuan, FENG Fan, et al. Remote sensing imagery classification based on attention mechanism and encoder-decoder network[J]. Journal of geomatics science and technology, 2020, 37(6): 610–615

[22] 刘敖迪, 杜学绘, 王娜, 等. 基于深度学习的ABAC访问控制策略自动化生成技术[J]. 通信学报, 2020, 41(12): 8–20

LIU Aodi, DU Xuehui, WANG Na, et al. ABAC access control policy generation technique based on deep learning[J]. Journal on communications, 2020, 41(12): 8–20

[23] 苏佳媛. 基于深度学习技术的智能化无人机视觉系统设计研究[J]. 工业设计, 2020(12): 152–153

SU Jiayuan. Research on the design of smart uav vision system based on deep learning technology[J]. Industrial design, 2020(12): 152–153

[24] KIM J, KIM J, HUONG L T T, et al. Long short term memory recurrent neural network classifier for intrusion detection[C]//2016 International Conference on Platform Technology and Service. Jeju: IEEE, 2016: 1?5.

[25] SANTOS D L, HUNSUCKER J L, DEAL D E. Global lower bounds for flow shops with multiple processors[J]. European journal of operational research, 1995, 80(1): 112–120.

- Similar References:

Memo

-

Last Update:

1900-01-01